Sewer Lining

Liners Eliminate Digging (and its Negative Repercussions!)

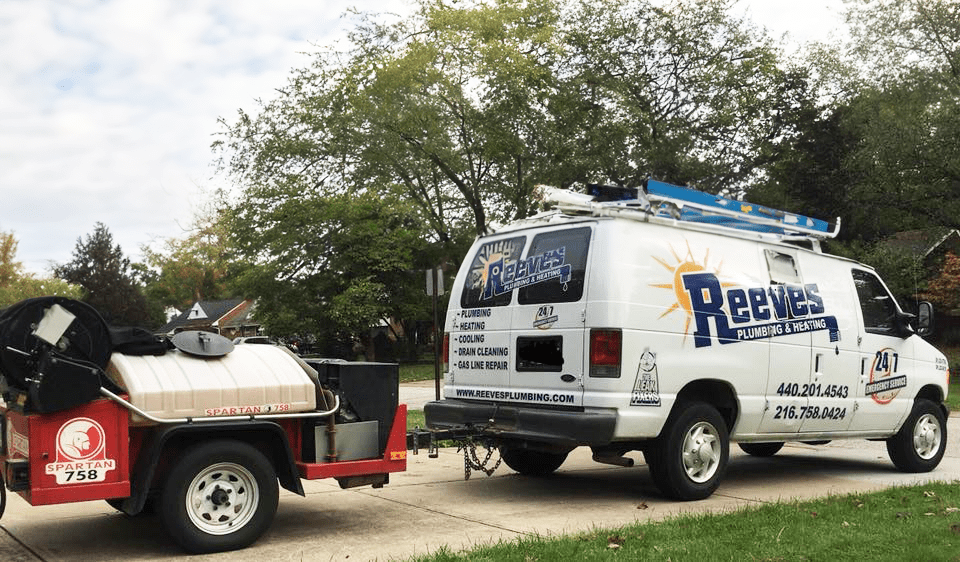

Reeves offers trenchless technology. Reeves can install a sewer liner for you to help minimize destruction to landscaping, concrete, and any large obstruction.

Sewer lining techniques, just like the other repairs classified as “trenchless technologies,” are referred to as such because they completely eliminate large-scale, costly digging from the repair equation by using cured in place pipeing (CIPP) solutions.

CIPP repair methods are made possible by liquid, epoxy-resin which are installed through the use of wall coating and air pressure. In these repairs, specialists use air bladders and small entry points to cure liquid liners in-place along the walls of your existing sewer pipe, avoiding all the hassles, damages and high landscaping costs of conventional sewer repair. When it comes to having sewer lines professionally renovated, trenchless, non-invasive solutions just make sense.